Stomp, a presenter at this year’s M-PACT Show who has worked with 80 fuel delivery companies in more than 10 states and consulted more than 100 other fuel companies, said there are two solutions that will cut costs and save the fuel industry. The first solution is tank monitors, which can result in fewer runouts, fewer trips, fewer accidents and reduced maintenance. The second solution is sales and safety automation, which means a smartphone with a safety/sales app in every employee’s hand

“The two together are the two primary ways that are going to help our industry move into the future,” Stomp said. “If companies don’t have these, they are crazy, absolutely crazy, and their competition will crush them.”

The First Monitors

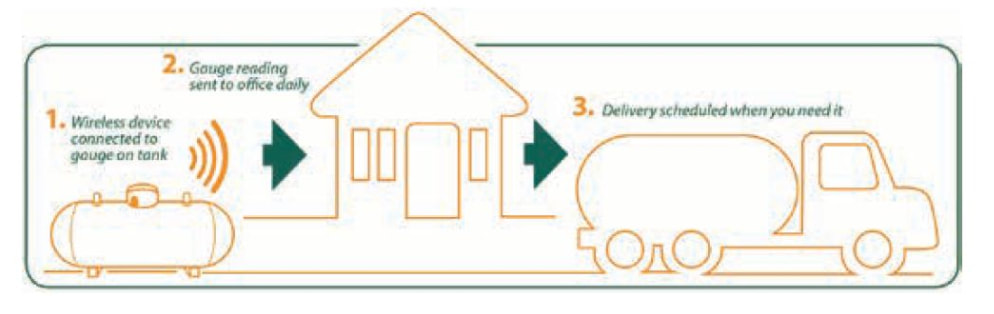

Tank monitoring, especially for large underground storage tanks, is nothing new. Many underground tanks are hard-wired to a building and have been attached for decades to show fuel levels and prevent leaking tanks from becoming environmental hazards.

“It’s an older but improving technology, been around for a long time, very connected,” Stomp said. “It’s almost every few seconds you’re getting a reading off this, and you really know what’s going on with the tank.”

The tank monitors for large gasoline, diesel, oil and kerosene tanks are much different than those used for propane tanks, but some companies have a fuel delivery and a propane delivery business, so they need monitoring systems for each, Stomp noted. And there are many options available.

“There are some tank monitors out there, believe it or not, that their specialty is being the tank monitor that works in the worst and most remote places in the world, and that’s where they’re the best,” Stomp said, mentioning places like offshore oil rigs, fracking sites and gold mines in Africa. These remote locations often require satellite-based communications, which are very expensive. Stomp compared other tank monitoring systems to vanilla ice cream, saying they are “good at everything but not great at anything.”

With such a range of tank monitors available, Stomp suggested fuel tank owners answer these three questions to find the best fit for their company:

- What kind of fuel do you have?

- What kind of tanks do you have?

- Where are you located?

“It’s not really a one-size-fits-all scenario,” he said.

Wi-Fi and Cellular Connections

Unlike expensive satellite-based systems, Wi-Fi is an easy, low-cost option for tank monitoring systems, most readily available in urban settings but with limited range. “You have to be within the range of this Wi-Fi repeater,” Stomp explained. Wi-Fi connections can also cause headaches when changes occur with passwords, internet routers or internet providers.

Cellular, while being a more expensive option, is more reliable and available in most residential and rural areas. “Cellular is awesome as long as there is cellphone signal. Cellular doesn’t reach to every area that propane tanks might be, or oil tanks or diesel tanks might be,” Stomp said. “I think, however, it’s the most reliable thing out there.”

Although currently reliable, an older cellular-based system may become obsolete. “Some monitors actively used in our industry right now work on 2G [second-generation technology]. Well, 2G is being phased out, and 5G is, hopefully, going to be phased in sometime,” Stomp explained. “So, if you have cellphone-based tank monitors that you’ve had for a few years, you may have thought, ‘Wow, this is great. I paid them off, and finally, I’m going to start making money on them.’ Then, you find out you’ve got to throw them away because 2G isn’t working anymore. … The only people making money on that is the tank monitoring guy who sold you that for lots of money.

“You’re going to want to get a solution that’s the newest thing out there, that’s going to last the longest and won’t become obsolete anytime soon,” Stomp added.

Another new wireless option, which Stomp described as extended-range Wi-Fi, requires attaching a mini cellphone tower to a church steeple, a barn roof or another tall structure. That creates a local area network for receivers within a few miles of the tower.

“There’s a lot of pain and a lot of potential risk with this whole [tank monitoring] thing. … With all that risk, one might wonder why would we even want to do this. It’s because the potential for benefit and savings is so high. People want to get the savings and the efficiencies that come with a monitoring system.”

– Bill Stomp, Partner at PropaneQuarterback.com and TankSpotter.com

ACCORDING TO BILL STOMP, PARTNER AT PROPANE QUARTERBACK AND TANK SPOTTER, TECHNOLOGY IS THE WAY.

Having so many options available can create more problems, leaving many wondering if investing in tank monitoring systems is worth the trouble. Stomp insisted it is. “There’s a lot of pain and a lot of potential risk with this whole thing. There’s risk if you get the wrong system. There’s risk they could cancel the 2G system now, and you’ve got to get new monitors. There’s risk if you put new Wi-Fi systems out there and people change their routers, and you have to go back out there to fix a monitor. And it’s $50 to $75 every time you send a guy out. With all that risk, one might wonder why would we even want to do this,” he said. “It’s because the potential for benefit and savings is so high. People want to get the savings and the efficiencies that come with a monitoring system.”

For those ready to find a tank monitor to fit their company’s needs, Stomp’s advice is, “Shop around. Contact my office. We have already done a lot of the summarizing of all the information. Find somebody that’s already tested them. There are some very interesting new solutions on the market like the Owl from Technology Assurance Labs. And make sure the monitoring system works with your company’s software, Stomp added.

New-Age Sales and Safety

With tank monitoring, some companies are better than others, but with safety and sales automation, no company is doing what Tank Spotter is doing, according to Stomp. The company has been successful because it combines optimizing sales, safety documents and marketing all on one Apple or Android app; uses off-the-shelf technology (smartphones and tablets); and was created by fuel industry veterans. But sales and safety automation isn’t unique to the fuel industry. According to Stomp, safety consulting companies have been doing this for years on desktop software, but the advent of smartphones makes it easier to do once and cut out the clerical work and double entry.

“In our industry, that would mean more sales, less safety issues, lower office admin costs,” he said. “If we can then cut the number of deliveries by 20 percent through tank monitoring, you have found a way to run your business more profitably and safer than you ever imagined possible. That is the new reality, the new possibility.”

To learn more about Tank Spotter’s Safety and Sales Automation App visit TankSpotter.com