Recently while speaking with Eric Leskinen of PropaneSafetyPro.com it became clear that managing properly the Propane Container Placement and Documentation could do much more one might expect.

The old adage that “the job’s not done until the paperwork is completed” still applies in the propane industry. Propane Safety Consultant, Trainer, Subject Matter Expert, and past President of the Propane Gas Defense Association, Eric Leskinen of PropaneSafetyPro.com would agree. Fortunately, time has moved on and technology has advanced so some believe that now we can use a simple smartphone to back up our paperwork with a photo but will that truly suffice?

The old adage that “the job’s not done until the paperwork is completed” still applies in the propane industry. Propane Safety Consultant, Trainer, Subject Matter Expert, and past President of the Propane Gas Defense Association, Eric Leskinen of PropaneSafetyPro.com would agree. Fortunately, time has moved on and technology has advanced so some believe that now we can use a simple smartphone to back up our paperwork with a photo but will that truly suffice?

For decades the propane industry has protected itself with mountains of paperwork carefully filed in bullet proof file cabinets. Paper documentation has always had its drawbacks such as it can be lost,

illegible, performed incorrectly, filed incorrectly, etc. The advent of digital photos provided some hope but legally proving the photos were taken at the day and time of installation or service work and prove

the viability of the whereabouts of those same pictures can provide a challenge. Add to this the challenge of coordinating and attaching the correct photos with the client’s physical files or digital files

can be extraordinarily difficult especially in the heat of the winter delivery season.

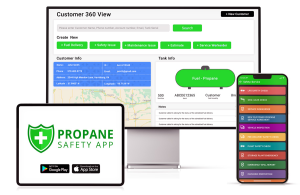

The advent of an app for both Apple and Android smartphones (and tablets) as seen in Eric’s Propane Safety App allows for much easier documentation with validation of photos that are authenticated with time, date and geocode capture validated by auto connecting them to the documentation and auto filing them with the customer digital file.

The next step is ensuring the propane container is placed properly and meets appropriate guidelines.

- Container Foundation: The ASME tank and DOT cylinder must be set properly on the correct foundation. Meeting appropriate guidelines for cylinders above ground secured properly on firm foundation or ASME tanks placed on masonry or other noncombustible structural supports.

- Container Location: Based on government codes and requirements the placement of propane containers must meet minimum separation distance from buildings, structural openings and any sources of ignition.

- Container Condition: Containers must be coated and painted appropriately to minimize corrosion and secondarily to promote company brand image.

- Container Documentation: Digital documentation now allows for photo, geo-code, date and time along with data validation and instant filing into a digital vault for safekeeping and quick retrieval

With the cost of propane containers and the cost of not documenting things properly it is critical to ensure that your employee team is appropriately trained to maintain these requirements while installing and servicing propane containers. Having written policies and procedures in place helps but to say it plainly, tracking and auditing every propane container in your company’s portfolio is a mountain of

work.

Using a photo documentation process will make meeting container placement requirements easier and help your team improve operational efficiencies along the way.

Tracking your containers and auditing them for compliance is a best practice recommended by propane safety experts to maintain compliance with government requirements and ensure that employees in the field are completing their responsibilities appropriately. It’s a great tool to not only help management with overall risk reduction, but to also evaluate technician performance and provide any necessary training feedback.When your delivery drivers are out on their routes and your service technicians are in the field, have them take photos of the container installations at each customer location they visit.

Fortunately, it is now easier than ever with the Propane Safety App. You’ll have direct visual documentation to include with the customer’s account showing that the tank set your company installed and/or serviced is compliant with government container requirements.It is a good idea to take a photo of every container that your company delivers to or installs and update that photo on a regular basis. When your drivers and service technicians are out in the field, have them take photos of any installations they identify as noncompliant. This will make sure noncompliant containers are recorded, followed up on, and corrected to help eliminate issues and risks for your company. Plus, taking a quick photo of a noncompliant container is much easier instead of filling out a report after the fact. Always remember, photo documentation is a helpful tool, but your employees should still utilize their training to visually inspect containers for compliance issues.No Photo Documentation? That Could Cost You.

Fortunately, it is now easier than ever with the Propane Safety App. You’ll have direct visual documentation to include with the customer’s account showing that the tank set your company installed and/or serviced is compliant with government container requirements.It is a good idea to take a photo of every container that your company delivers to or installs and update that photo on a regular basis. When your drivers and service technicians are out in the field, have them take photos of any installations they identify as noncompliant. This will make sure noncompliant containers are recorded, followed up on, and corrected to help eliminate issues and risks for your company. Plus, taking a quick photo of a noncompliant container is much easier instead of filling out a report after the fact. Always remember, photo documentation is a helpful tool, but your employees should still utilize their training to visually inspect containers for compliance issues.No Photo Documentation? That Could Cost You.So, we’ve talked about the benefits of implementing a photo documentation process into your company’s operations, but what exactly are the risks of skipping it all together? One of the greatest threats to a propane company is the DIY homeowner. From obstructing containers with objects or renovations to completely moving the container set all together, nothing is unheard of in our industry. And any scenario you might think of could result in a safety hazard, and a lawsuit for your company.

In a situation like this, having clear photo documentation that the container in question was compliant with local and regional government requirements will help to protect your company from liability in the event of litigation. And even more likely, a photo documentation process will help avoid unnecessary safety hazards to better protect your customers in the long run, too.

to the industry and for his thoughts along these lines. If you want to connect with him for training, creating appropriate manuals or to see his Propane Safety App you can connect with him on his site PropaneSafetyPro.com.

to the industry and for his thoughts along these lines. If you want to connect with him for training, creating appropriate manuals or to see his Propane Safety App you can connect with him on his site PropaneSafetyPro.com.